What can a company participating in the production solutions program gain?

The company gains experience in understanding the role that robotization could play in its production. The company has the opportunity to:

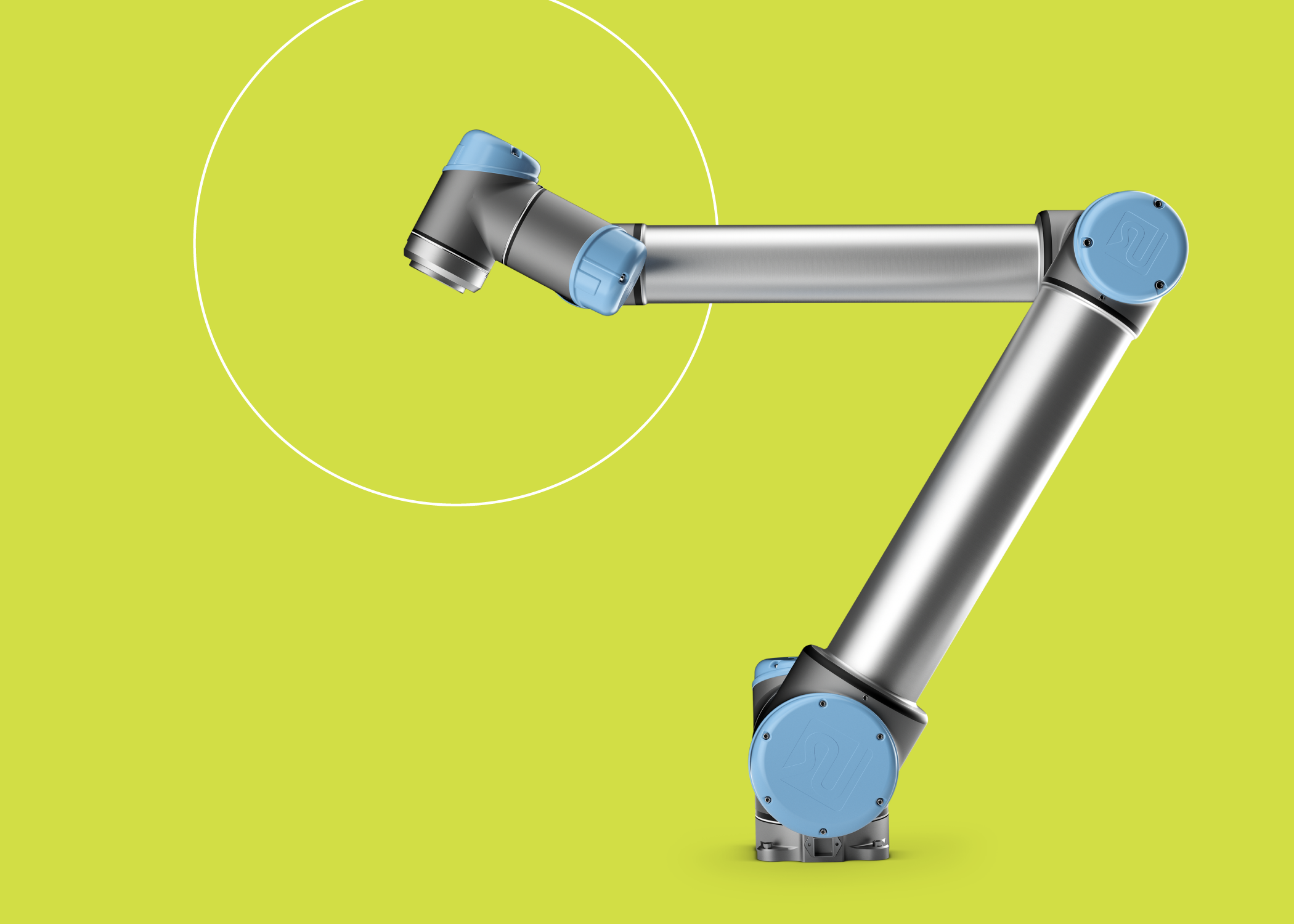

- Experiment with robotic grinding or robotic machine tool servicing;

- Test the insertion or reception of parts;

- Find a suitable work organization solution for its production;

- Simulate the replacement of a human with a robot in real life.

The program will conclude with a result report, which includes:

- A description of the problem outlined in the initial task;

- Mapping and analysis of the current state of the process being developed;

- A brief overview of alternative solutions;

- A description of the activities carried out during the development process (including, if necessary, an overview of the results of these activities);

- Proposals for the implementation of innovative production solutions and related changes in production organization (including associated calculations and technical descriptions);

- The potential benefits derived from the solutions.

The report may also conclude that under the given conditions, the implementation of the investigated solution is not feasible, or that other necessary preliminary activities must first be carried out for the implementation of the investigated solution.

Who is the production solutions program intended for?

The production solutions program is intended for small or medium-sized enterprises engaged in batch production (repetitive parts) or where manual grinding with orbital sanding equipment is used.

What is the cost of participating in the production solutions program?

The cost of one project in the production solution is up to 6,000 euros, which is considered de minimis aid (VTA). The recipient of the aid must have a de minimis aid balance greater than the aid received.

How to participate in the production solutions program?

Before applying for the program, it is advisable to undergo preliminary consultation, during which the initial task is described and a projected cost estimate for the project can be made. Write to to schedule a time.

After the preliminary consultation, an application must be submitted, detailing the company’s previous experience with automation and robotization and the problem the project aims to solve.

Download the application form here, fill it out, and send it digitally signed to . Applications for the program are open on an ongoing basis. For more detailed conditions, see here.

For questions, contact Erkki Naaris at or +372 518 9386.

The support is provided and implemented by the Wood Competence Center TSENTER of Võru County Education and Technology Centre, co-funded by the European Union within the framework of the project “Developing the business ecosystem in South-East Estonia”. Read more about the project.