Wemel Wood is the first in the world to introduce a series of 100% recyclable thermowood switches, sockets, and their frames, combining environmental sustainability with design in their product line.

Wemel Wood was one of the first companies to take advantage of the opportunity to develop its product through TSENTER’s product development program. The goal of this program is to help sector companies make their products more competitive and increase export potential.

TSENTER has previous experience with Wemel Wood through the EIS Innovatsiooniosak measure, during which the company approached TSENTER to develop and test the design, technology, and materials of wooden electrical sockets and switches. The first collaboration project was successful, so Wemel Wood took the opportunity to collaborate with TSENTER again. This time, the finishing technology needed development. “We were mainly motivated to join the program by TSENTER’s good competence in wood processing. It’s not worth inventing everything yourself, and the more we can use the help of professionals in our field, the faster and more efficient the product development,” said Karl Haljasmets, co-founder of Wemel Wood.

The project’s goal was to develop the technology and methodology for finishing electrical sockets and switches made from intensively treated thermally modified ash. It was necessary to find a suitable finishing material that meets the given conditions:

- Industrially applicable

- Water-based or as ecological as possible

- Mechanically resistant to wear, UV radiation, and cleaning chemicals used in public spaces

- Possible to tint in various light and contrasting shades

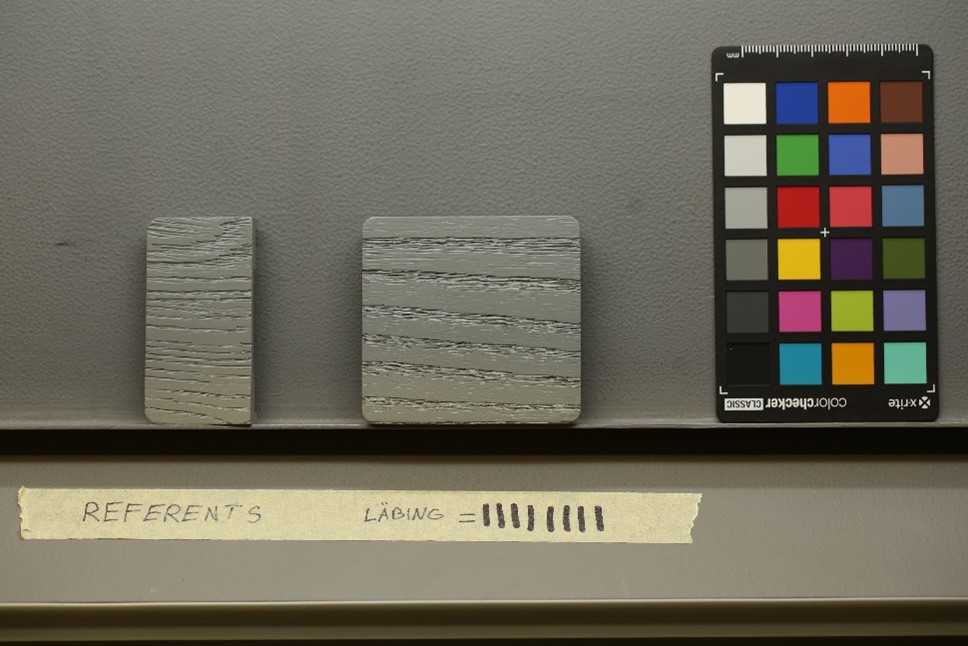

The project lasted six months, during which 13 different finishing materials were tested. The best-performing finishing material was then subjected to laboratory tests:

1. Abrasion resistance test to assess the finishing material’s resistance to mechanical wear (non-abrasive wear). The test was conducted following the standard: “Paints and varnishes – Determination of resistance to abrasion – Part 2: Method with abrasive rubber wheels and rotating test specimen,” EVS-EN ISO 7784-2:2023.

- Abrasiivi tester QC-619T

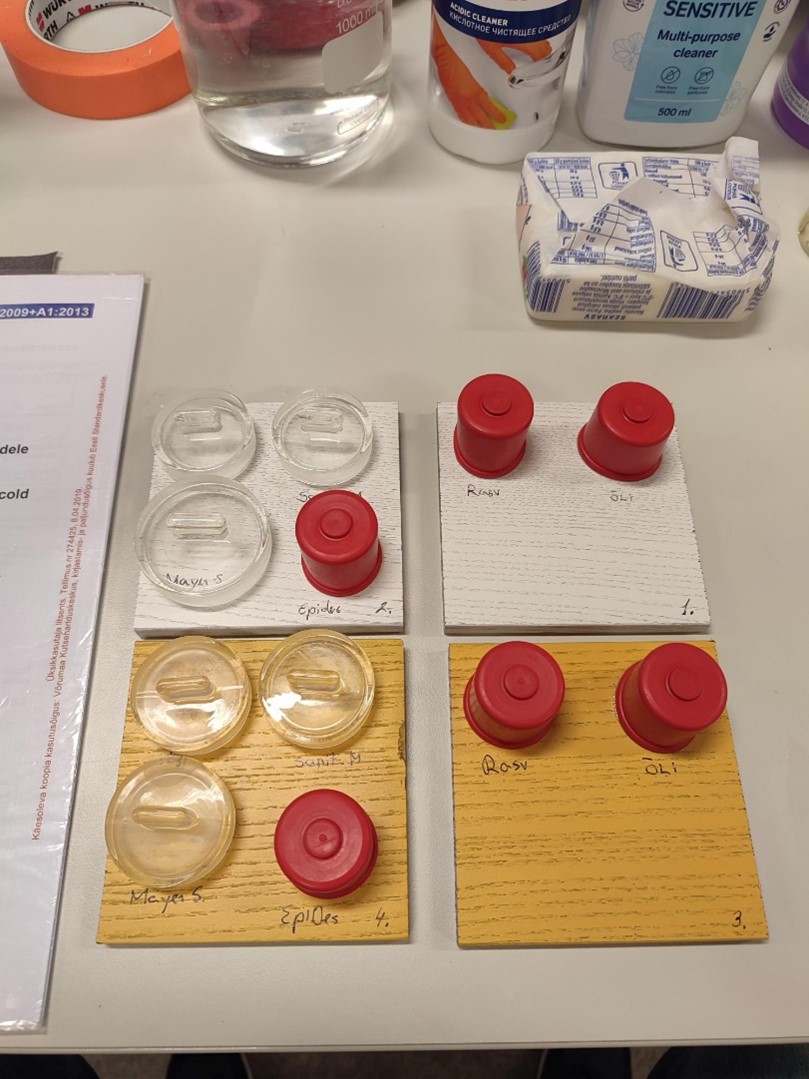

2. The finishing material’s resistance to chemicals was tested according to the standard: “Furniture. Assessment of surface resistance to cold liquids,” EVS-EN 12720:2009+A1:2013. The chemicals tested included:

- Lard

- Cooking oil

- Water (H2O)

- Mayeri sensitive Multi-Purpose cleaner

- Sanit-M Acidic cleaner

- EPIdes Strong. Ethanol 73.5%

3. The finishing material’s resistance to UV radiation

Additionally, the technology for finishing these components was developed, and the consumption norm of the finishing material and the processing cycle time were calculated. If the project is successful, new color shades will be added to the product line. “Our goal is that in the future, our products can be ordered in the entire RAL color range,” Karl adds in conclusion.

Read more about the product development service here.

The activity was carried out by the Võrumaa Education and Technology Center’s Wood Competence Center TSENTER with the co-financing of the European Union within the project “Development of the Southeast Estonia Entrepreneurial Ecosystem”. Read more about the project.