Every valuable idea thrives when it receives the right support

| DEVICE NAME | DESCRIPTION | |

|---|---|---|

|

Brushing machine

|

Brushing / aging of the material with two different drums | |

|

Brushing / aging of the material with two different drums

|

||

|

5-axis CNC

|

For processing complex forms and models | |

|

For processing complex forms and models

|

||

|

3-axis CNC Busellato

|

Nesting + pads 3-axis CNC | |

|

Nesting + pads 3-axis CNC

|

||

|

3-axis CNC Stepcraft M500

|

Router CNC working area 348 x 543 x 194 mm | |

|

Router CNC working area 348 x 543 x 194 mm

|

||

|

3D scanner for small objects

|

Scans geometry and texture on 50-200 mm objects | |

|

Scans geometry and texture on 50-200 mm objects

|

||

|

3D printer

|

Work area 300 x 300 x 300 mm | |

|

Work area 300 x 300 x 300 mm

|

||

|

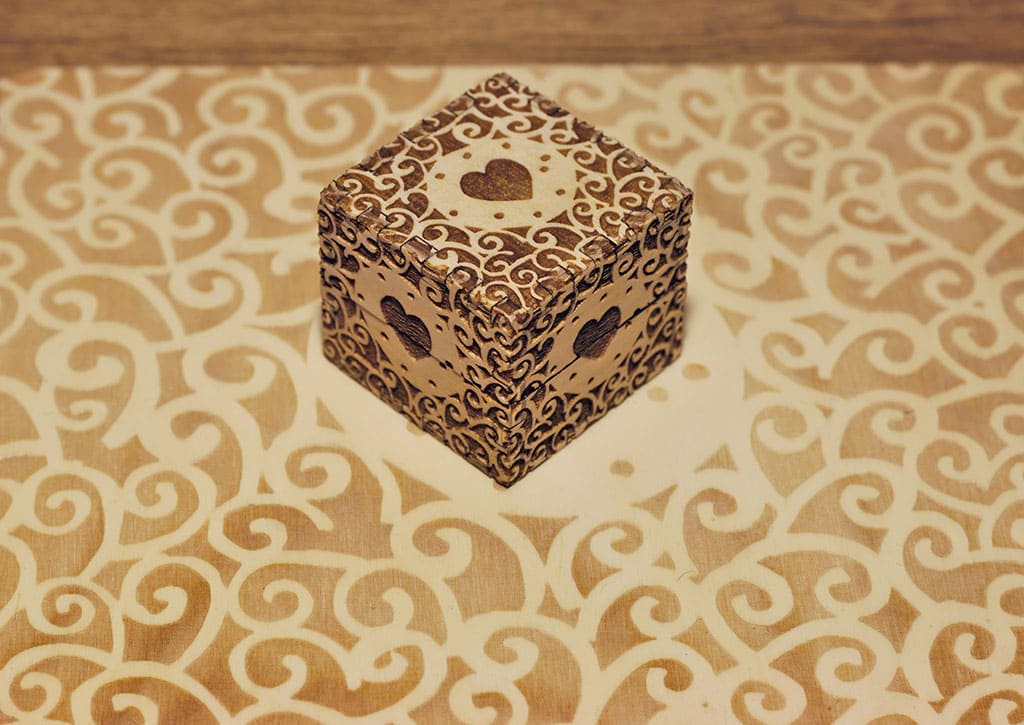

Laser cutting machine

|

For cutting and engraving wood. With a working area of 600 × 900 mm | |

|

For cutting and engraving wood. With a working area of 600 × 900 mm

|

||

|

A set of hand spray equipment, with a chamber

|

Low and high pressure | |

|

Low and high pressure

Hand spray equipment:

Spray chamber:

|

||

|

Spray machine

|

Industrial finishing line paper on conveyor, traverse method | |

|

Industrial finishing line paper on conveyor, traverse method

|

||

|

Surface printing machine

|

UV printer with a working area of 1550 x 3000 mm, material thickness 3 – 95 mm | |

|

UV printer with a working area of 1550 x 3000 mm, material thickness 3 – 95 mm

|

||

|

Format saw

|

Cutting wood and board material. Slide travel 3200 mm | |

|

Cutting wood and board material. Slide travel 3200 mm

|

||

|

Edge belt sander

|

Wood and board material for grinding the edge of parts | |

|

Wood and board material for grinding the edge of parts

|

||

|

Wide belt sander

|

Calibration of the board material and intermediate sanding of the finishing material | |

|

Calibration of the board material and intermediate sanding of the finishing material

|

||

|

Milling machine

|

Milling machine with slide for milling tenons and profiles | |

|

Milling machine with slide for milling tenons and profiles

|

||

|

Combined planer/thickness machine

|

For planing solid wood | |

|

For planing solid wood

|

||

|

Band saw

|

For dissecting wooden material or cutting curved parts | |

|

For dissecting wooden material or cutting curved parts

|

||

|

Brush sander

|

FlexTrim. For sanding curved parts | |

|

FlexTrim. For sanding curved parts

|

||

|

Multi-spindle drill press

|

For drilling horizontal and vertical holes | |

|

For drilling horizontal and vertical holes

|

||

|

Column drill press

|

For drilling vertical holes | |

|

For drilling vertical holes

|

||

|

Manual edge banding machine

|

For edge protection of both straight and curved sheet materials | |

|

For edge protection of both straight and curved sheet materials

|

||

|

Hand CNC machine Shaper Origin

|

A router that combines the precision of CNC with the ease of use of a hand tool | |

|

A router that combines the precision of CNC with the ease of use of a hand tool

|

||

|

Collaboration robot UR10e

|

To carry out robotization experiments | |

|

To carry out robotization experiments

|

||

|

Logistics robot MiR250

|

To carry out robotization experiments | |

|

To carry out robotization experiments

|

||

|

Laboratory equipment

|

To monitor finish quality |